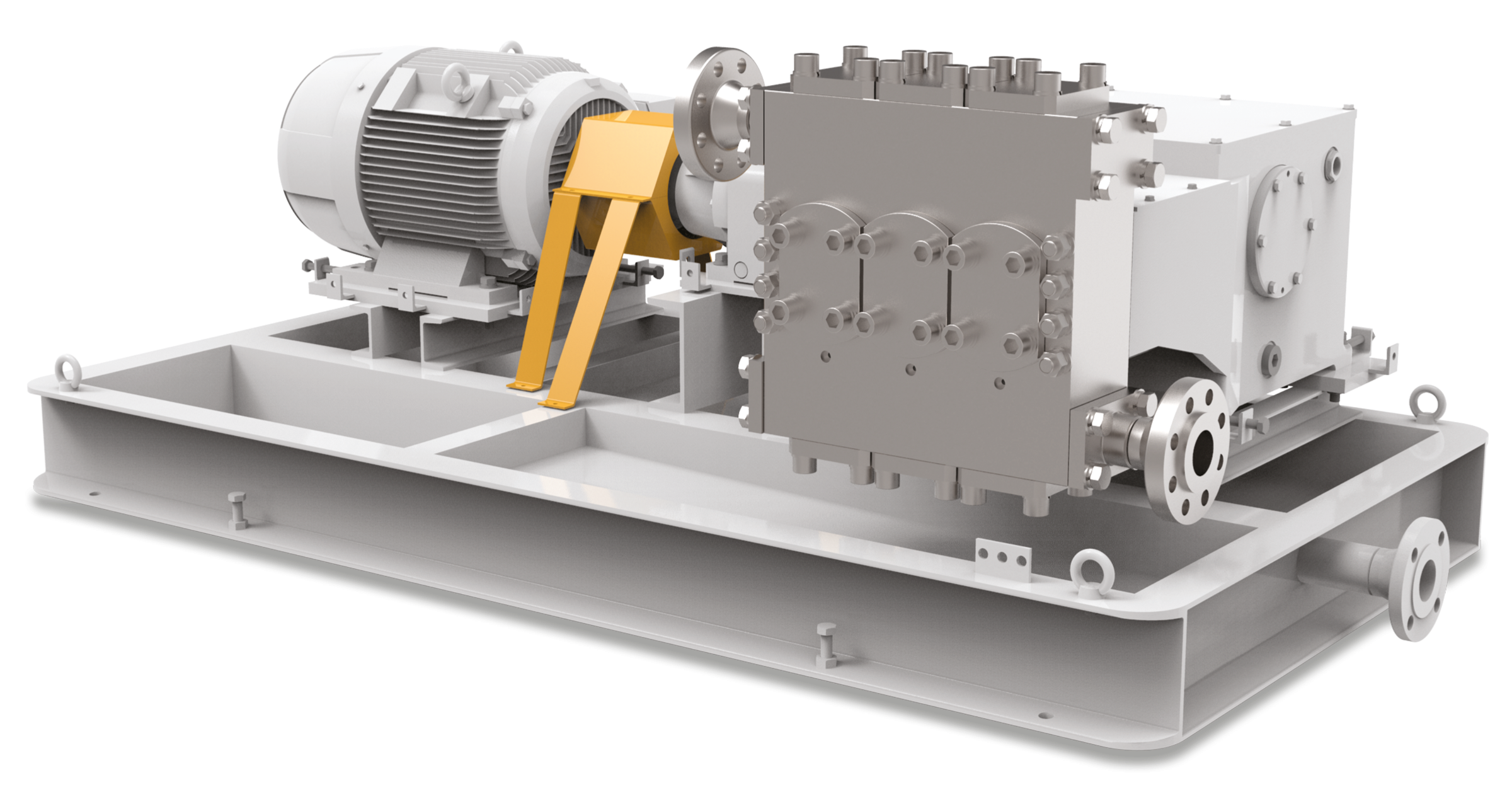

3C Triplex Pumps Series

Process pumps for high-pressure duties

A UNIQUE DESIGN

3C Triplex Pumps Series Process pumps for high-pressure duties

A flexible, robust and reliable solution to pumping high temperature, abrasive and viscous liquids in a multitude of industrial applications, the 3C Triplex pump series offers the best total cost of ownership available on the market.

3C Triplex pumps are designed in accordance with API 674 standards and can be customized to achieve special operating requirements, allowing the customer to build the ideal system for the unique demands of their application.

A flexible, robust and reliable solution to pumping high temperature, abrasive and viscous liquids in a multitude of industrial applications, the 3C Triplex pump series offers the best total cost of ownership available on the market.

3C Triplex pumps are designed in accordance with API 674 standards and can be customized to achieve special operating requirements, allowing the customer to build the ideal system for the unique demands of their application.

Technical Features

| Capacity Range | up to 65,000 l/h, up to 1150 bar |

|---|---|

| Wetted Parts | SS 316 L, LTCS, Super Duplex, different material (on request) |

| Flow rate adjustment | by frequency converter |

| Compliance | with international standard approvals as API 674, ASME, TR CU 012/2011 |

Enhance your spring pump with

Accessories

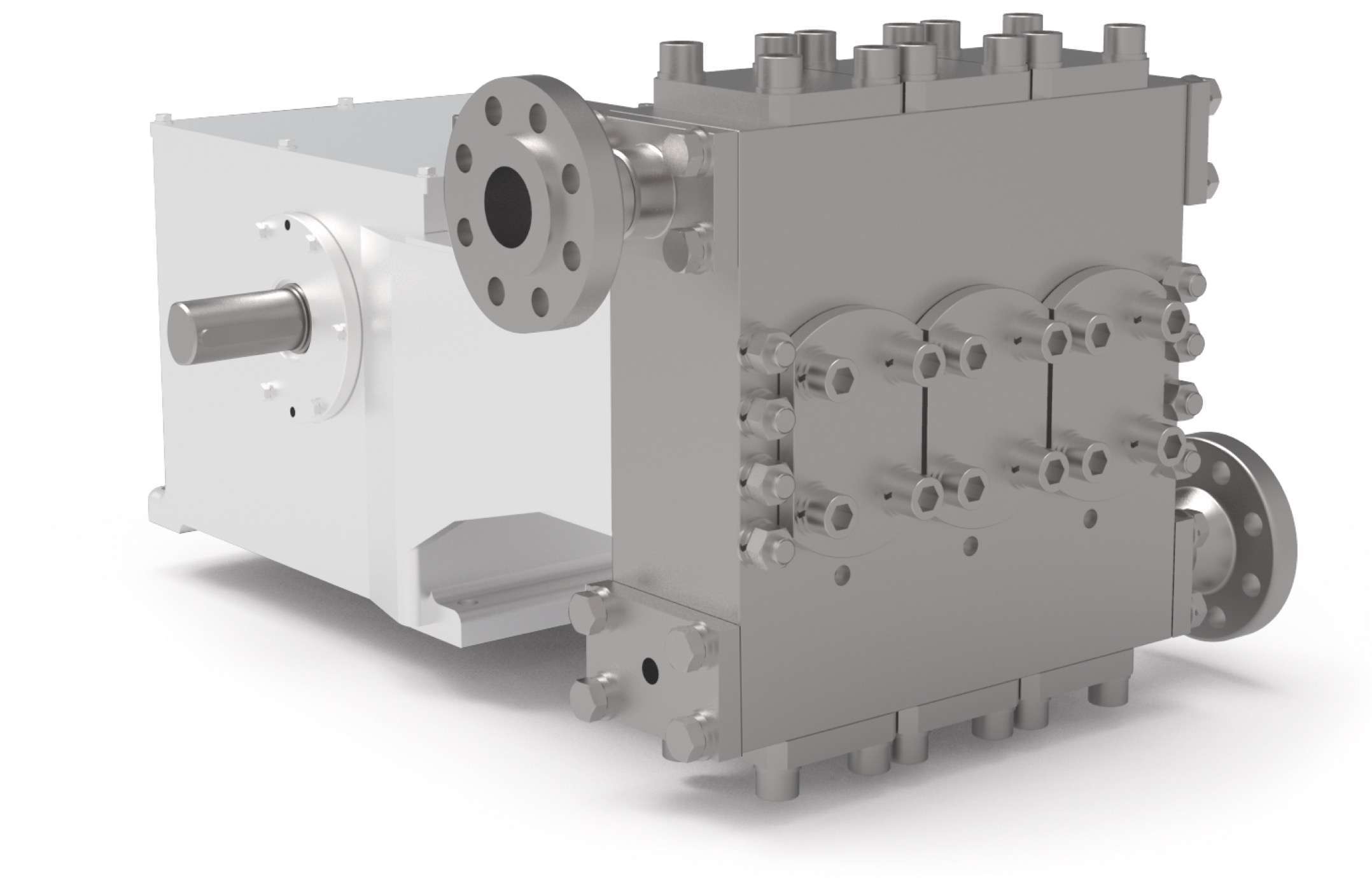

Pump Heads

- Wetted parts: 316L or 304 stainless steel, duplex steel or carbon steel (exotic alloys available upon request)

- The three-cylinder pump head is horizontally arranged, with single-acting plungers and valves and seats that can be selected among different executions depending on the handled fluid

- Plungers and packing are easily maintained, with replacement of components for most pump sizes possible without disconnecting the pump from the pipework

- Optional “leakage return to suction” and flushing of stuffing box guarantee a virtually leakage free process and for a longer packing life

Mechanism

The unique design of the 3C Triplex mechanism allows the pump to operate at a very low speed without forced lubrication, making it ideal for applications requiring a slow plunger motion to avoid cavitation when pumping hot or viscous liquids or fluids with high vapour pressure. The range features:

- Silent and vibration-free operation due to proper mass balancing and sizing. The integral crankshaft and crossheads are supported at both ends, giving precise alignment of the plunger rods for a longer sealing life

- A compact and robust assembly, providing high performance within a minimal footprint

- Low-speed operation, resulting in reduced wear of moving parts and high reliability

Advantages at a glance

Customization

With Exakta's support at every stage, these pumps are designed around customers’ requests, with a wide choice of wetted parts, leakage control and collection, paint colour, documentation and certification.

Peace of mind solution

3C Triplex pumps can be supplied as part of a complete packaged solution by combining them with fully-compatible in-house designed accessories such as safety valves and pulsation dampers or any subvendor ancillaries (motor, reducer, coupling, instrumentation) for a smooth pumping operation.

Reliability

With their outstanding build quality, premium components, low TCO (Total Cost of Ownership) and long MTBF, 3C Triplex pumps embody Exaktas’ core values of reliability and robustness, in addition to the durability to withstand temperature extremes, aggressive chemicals and other severe operating conditions encountered in heavy-industrial applications.

Industry Applications

Oil & Gas

Fertilizers

Oleochemicals

Food & Beverage

Ceramics

Metal & Mining

You might be interested in

Need our Help?

Contact Us

Your request has been sent!

A member of our team will be contact shortly